Plug & Play Cobot Welder

Robot Welding. Purpose Built. Production Ready

SOLUTIONS

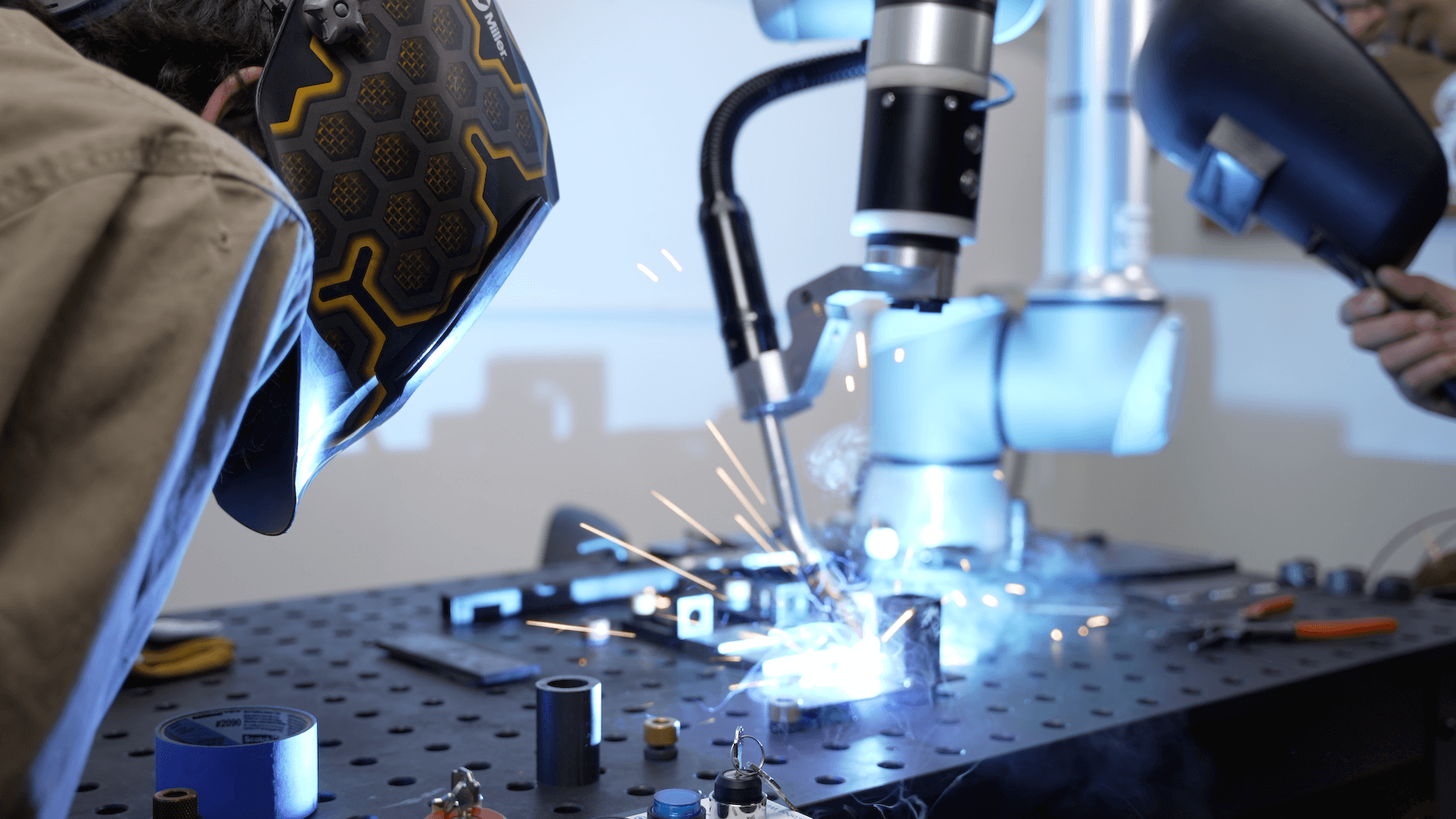

Meet the Cobot Welder That’s Revolutionizing Shop Floors

Help your team weld faster, safer, and with more precision. Hirebotics cobot welders, powered by the Beacon platform. No programming. No downtime. No specialists.

Fast Setup

Traditional automation can take weeks to deploy. The Cobot Welder is ready in hours. Your team installs it, loads a job, and starts welding without waiting for engineering support or coding help.

Consistent Welds

Clean, repeatable welds are standard with the Cobot Welder. Each pass matches the last, helping reduce rework and ensure every part moves down the line without a hitch.

No Programming

Beacon gives your team intuitive tools they already understand. No code, no complex interfaces. Jobs are created with drag-and-drop steps that your welders can control from a tablet or phone.

Weld More Jobs Per Shift

Cobot Welders can run all day and all night. With repeatable job paths and easy resets, your shop can complete short runs, big batches, or mixed orders without re-configuring your entire workflow.

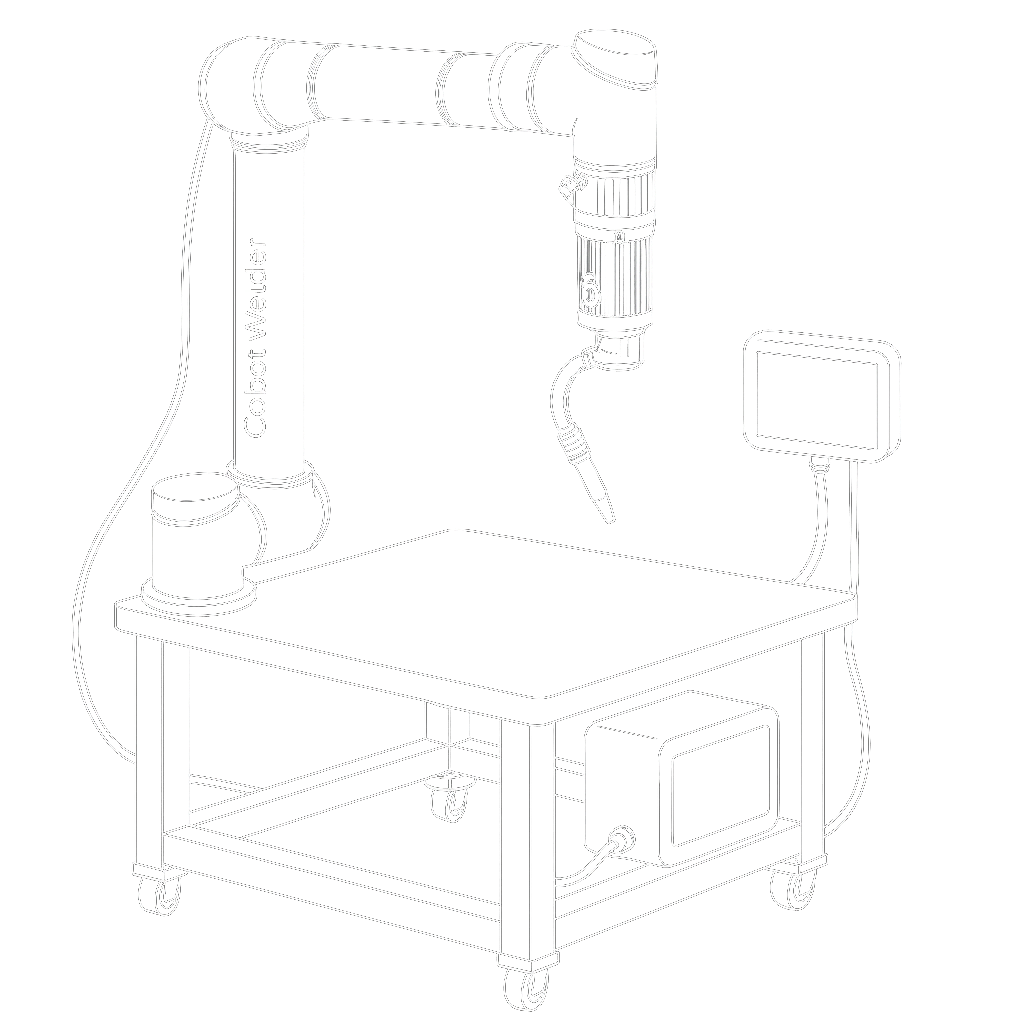

Cobot Welder Package

What is included in the Cobot Welder package?

Core Package

Welding automation, simplified.

Get started with everything you need on day one. Core is pre-mounted, pre-wired, mobile and ready to run out of the box — no third parties, no delays. Perfect for shops new to automation or needing a space-saving setup.

Starting at $105k

Robot

Universal Robots UR8 Long (68.9″ reach) collaborative robot

Power

Miller Auto Deltaweld 350

(Optional upgrade: OTC P 400-L or Deltaweld 500)

Welding Torch (Air-Cooled)

Air-cooled Tregaskiss Tough Gun® MIG Torch

Operator Panel

Operator controls with emergency stop

Table

Mobile cart workstation 48″ x 32″

Software

Beacon standard software

Smart Puck for tap-to-teach programming

Beacon Pro, optional

Beacon Care, optional

Accessories

17 piece essential consumables kit

(5) .045″ contact tips

(5) .035″ contact tips

(2) nozzles

(2) gas diffusers

(2) air filters

(1) teach tip

Explore the App

Program the Cobot Welder with your phone or tablet

See how simple programming can be. This quick video shows how you can use the Beacon app on your phone or tablet to set up, teach, and manage welding jobs—no coding or robotics experience required.

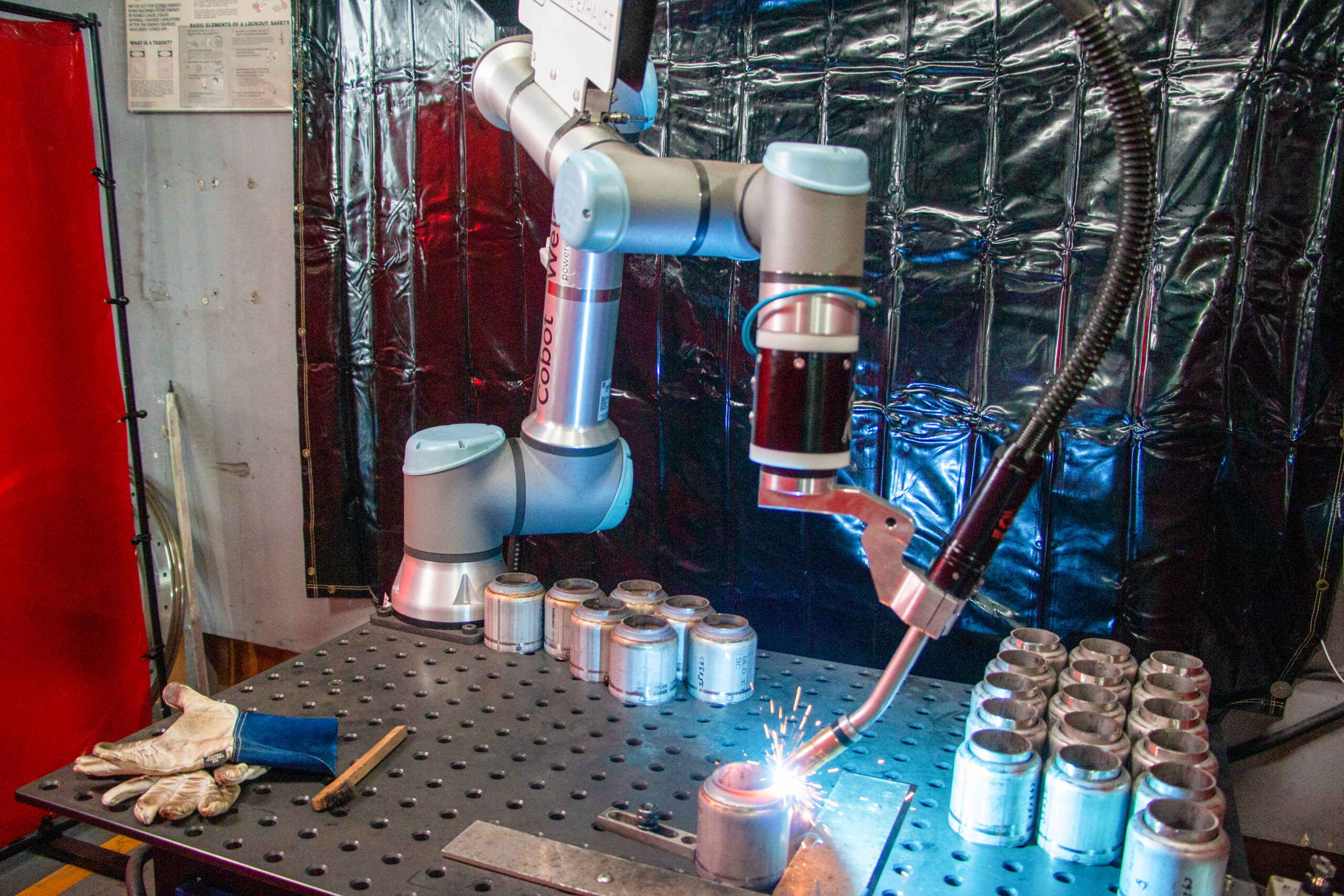

Capabilities

See what our cobot welder can do for you

Whether you’re scaling production or tackling one-off prototypes, our cobot welder is built to flex with your workflow. From MIG welding to small-batch automation, it combines the precision and consistency of a skilled welder with the simplicity of intuitive, no-code controls—so your team can do more, faster.

Welding Automation

Take the complexity out of automation and empower your team to boost productivity —our cobot welding solutions deliver consistent, high‑quality welds with minimal setup, all without needing a robotics expert.

MIG Welding

From thick plate to thin gauge, our cobot MIG welding system is built for speed, repeatability, and ease—helping you meet demand and maintain quality without manual strain.

TIG Welding

Get TIG-like precision, without the complexity. Our cobot delivers smooth, high-quality MIG welds that closely mimic the precision of TIG—without the need for manual finesse or complex setups.

Rapid Prototyping/Small-Batch

Ideal for short runs and quick-turn projects, our cobots give you the flexibility to efficiently weld small batches and prototypes without reprogramming or long setup times.

HOW IT WORKS

From Demo to Deployment in Four Steps

01

Schedule a Demo

See how the Cobot Welder fits into your production. Get hands-on insight from our team.

02

Register your cobot

We’ll help you select the right model, configure your tools, and prepare for deployment.

03

Click-and-teach paths

Use Beacon’s visual programming to set weld paths fast. Edit and reload on the fly.

04

Boost Productivity

Start welding and tracking output right away with production data like cycle times, gas consumption, and parts produced.

Case Studies

“In addition to decreasing production times, we have increased the reliability and uniformity of each part.”

Mark Moye

Plant Manager, Advanta Southeast

FAQs

You Have Questions, We Have Answers

What kind of ROI can Cobot Welder provide to my shop?

Depending on your production factors, cobots can 2-10X your fabrication productivity. Most shops see 2-4X the production output, saving them significant labor hours and freeing their staff to work manually on tasks that matter the most.

Read our case studies to get a better idea of just how powerful cobots can be.

Can I weld aluminum with the Cobot Welder?

Yes, you can! Just like you would MIG weld aluminum manually, with a few settings and accessory adjustments, and you can produce high-quality aluminum welds.

Will Cobot Welder weld my parts?

Our Cobot Welder can complete most repetitive welding tasks, but the part suitability depends on the part size, material type, and more. The best way to know for sure is to reach out to us for a demo so we can best assess your application needs.

How fast can I weld with a Cobot Welder?

The cobot’s maximum speed is approximately 39 inches per second (1 meter). However, when welding, the Cobot Welder can weld up to 90 inches per minute. This is extremely fast—far faster than a human can weld, giving you extremely low heat input and maximum productivity.

However, if you need to weld faster, contact us so we can better understand your needs.

Can I replace manual TIG welding with the Cobot Welder?

Indeed! We have a great article explaining how one of our clients got TIG-quality welds with the Cobot Welder.

They were able to speed up their TIG welding from 2 to 5 inches a minute up to 20 inches a minute! This enabled them to clear their daunting backlog in just a few weeks!

What type of support do you offer?

Our in-app chat support is built right into the Beacon interface! On average, we respond in 2 minutes directly in your Beacon app.

Do I need to buy the Cobot Welder to see if my fab shop will benefit from it?

You don’t need to! After our demonstration, you can enter our rent-to-own program and fully commit once you are ready.

What is the lead time for getting the Cobot Welder?

Generally, our lead time is approximately two weeks from receiving your PO.

Reach out to us anytime about our current lead time if you need a system sooner!

What do I need to know about safety when cobot welding?

While cobots have numerous safety features built-in and do not require safety cages like traditional automation, there are some important safety items to keep in mind when cobot welding.

Most importantly and just like manual welding, your welders need proper PPE. You’ll also want to make sure you protect your welders with arc flash protection like you do for your manual weld stations. And don’t forget fume extraction.