The Customer

Advanta Southeast boosts output by 400% with Hirebotics Cobot Welder

From stalled jobs to record production – how one metal fabrication shop reimagined its future with Hirebotics

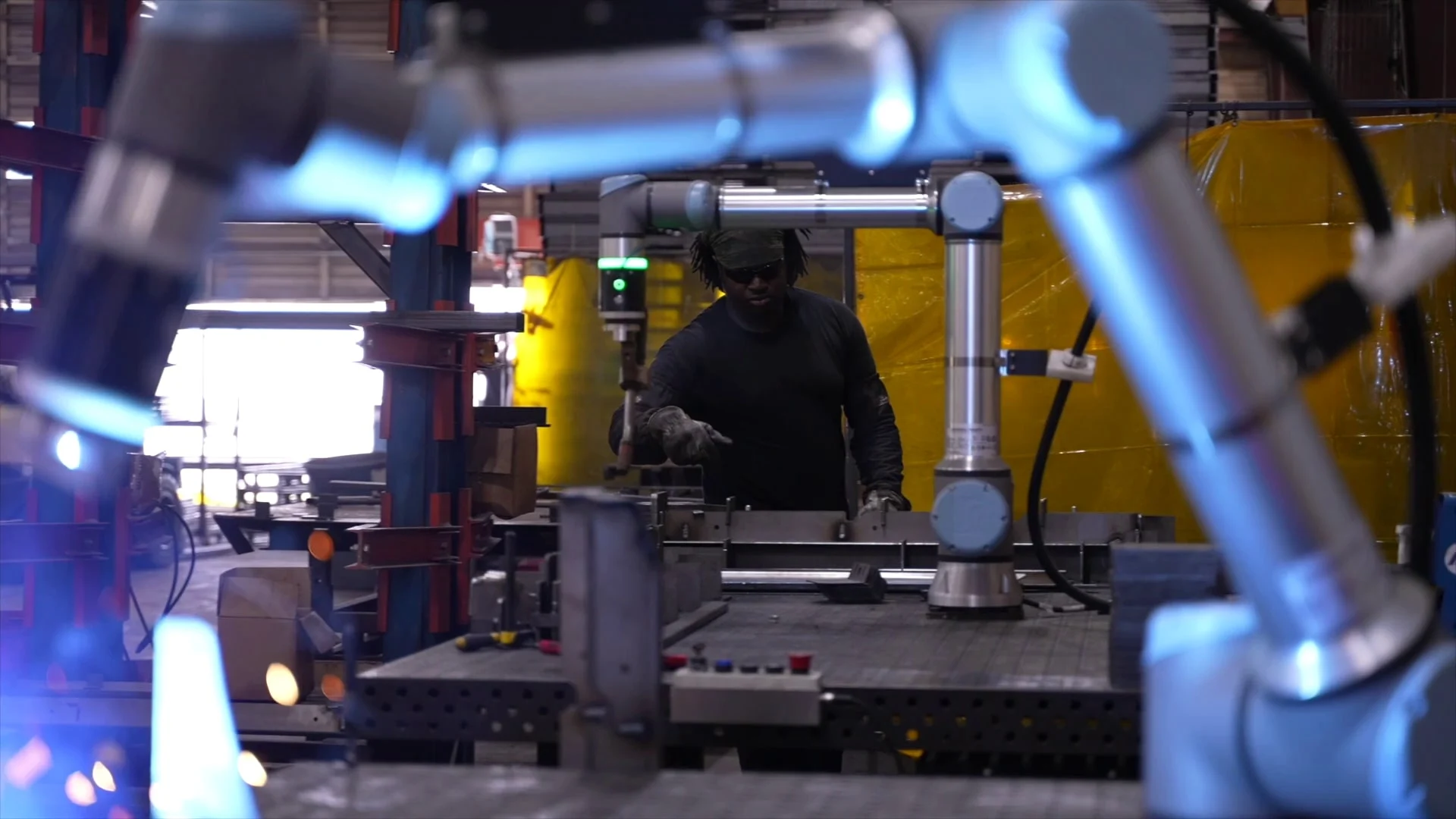

Advanta Southeast, a division of Advanta Industries, provides full-service metal fabrication for automotive, defense, energy, and marine sectors. Like many manufacturers, they were feeling the pressure: a tight labor market, unpredictable attendance, and rising demand made it harder – and riskier – to deliver on time.

WATCH THE VIDEO

“We needed a solution that didn’t depend on having the perfect welder show up every day. We needed consistency, flexibility, and something that just worked.”

Mark Moye

Plant Manager, Advanta Southeast

The Challenge

Advanta’s Search for a Smarter, Simpler Way to Weld

The team at Advanta was facing a three-part problem:

- Fewer skilled welders available and high competition to hire them

- Unpredictable attendance impacting throughput

- No time or resources to train staff on traditional robotic systems

They had looked at robotic automation before, but every option seemed too complicated – or too slow to get started. Long lead times, steep learning curves, and the need for specialized programmers didn’t fit the pace of their operation.

The Turning Point

Everything Changed When They Discovered Hirebotics

“Our first Beacon welder arrived within two weeks. By the end of that same day, we were welding parts. That never happens with robotics.”

– Mark Moye, Plant Manager, Advanta Southeast

What started as a cautious trial turned into a major turning point. With zero robotics experience, the Advanta team had the system unboxed, set up, and running in just a few hours. Even their manual welders were up and running on the interface in less than a day.

“The biggest surprise? Our welders actually liked it. They saw right away that it didn’t replace them – it made their work easier and let them focus on the harder, more rewarding jobs.”

– Mark Moye, Plant Manager, Advanta Southeast

The Impact

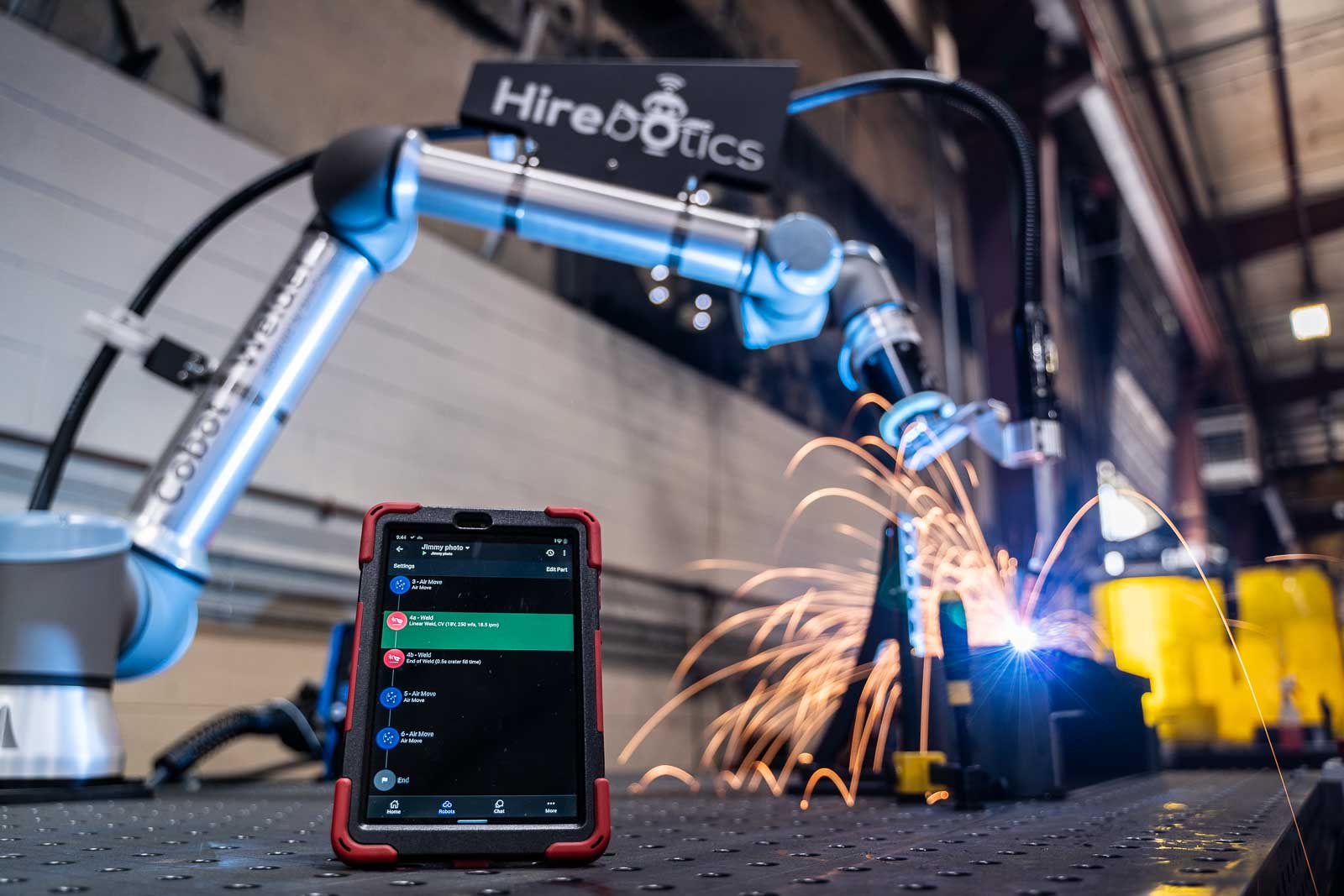

Production Jumped From 25 to 100 Units Per Day

That’s a 400% increase, driven entirely by one cobot station.

And it wasn’t just volume. Beacon’s built-in Beacon OS app gave them full visibility into performance insights of every weld in real time – from part counts to gas and wire usage to shift productivity.

“We’re not guessing anymore. We can see the data, track performance, and make smarter decisions. That’s a big deal.”

– Mark Moye, Plant Manager, Advanta Southeast

The team also found in-app support refreshingly fast.

“We’ve only needed help twice in nearly eight months. Each time, it was solved in under 30 minutes.”

– Mark Moye, Plant Manager, Advanta Southeast

The Expansion

Hirebotics Helped Them Grow — Not Just Automate

With such a strong ROI, Advanta added three more cobot welders to the South Carolina plant – and expanded the solution to their Michigan facility, too.

Just a few months in, the added capacity helped them win contracts they wouldn’t have been able to take on before – including large-scale fabrication for an electric vehicle manufacturer.

“If someone’s on the fence about Hirebotics, I’d tell them – jump in. You won’t regret it.”

– Mark Moye, Plant Manager

Hirebotics didn’t just help Advanta Southeast automate welding. It helped them scale their business, empower their team, and take on the kind of work that drives growth.