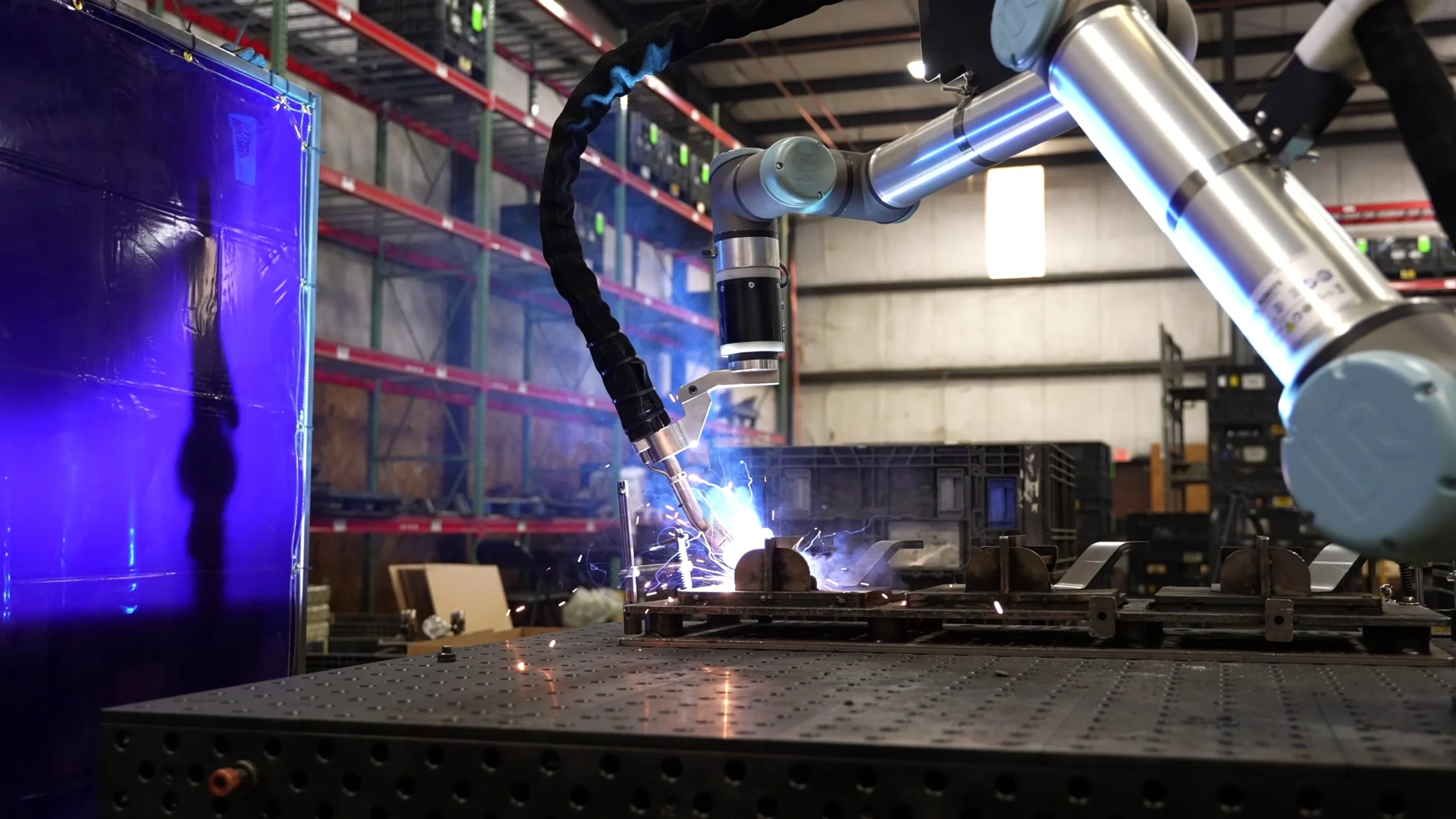

Aesthetic Welds Without the Bottlenecks

Get TIG-Like Quality With Robotic MIG

CAPABILITIES

Boost Efficiency With Automated Robotic TIG Welding

Our robotic welding systems deliver the precision and consistency you expect from TIG, with MIG that’s faster setup and simpler operation. Beacon helps shops eliminate bottlenecks while keeping quality high.

- Consistent, clean welds with minimal rework

- Faster cycle times for higher throughput

- Easy to learn, easy to run with no coding required

- Free up skilled welders for high-value work

Beacon makes precision welding scalable without sacrificing craft.

Faster Weld Times

MIG welding offers quicker production cycles compared to TIG, which is ideal for high-volume projects.

Cost Efficiency

MIG requires less setup time and fewer consumables, cutting down on overhead costs.

Cobot Compatibility

Our cobot is optimized for MIG, allowing you to automate and scale production without sacrificing quality.

Making the Switch

Consider Making the Switch From TIG to MIG With Cobots

Why Shops are Switching:

Many fabricators choose TIG for its clean appearance and precision. But TIG can be slow, labor-intensive, and difficult to scale. With Beacon-powered MIG cobots, shops get the same smooth, consistent look — with faster throughput, easier setup, and less strain on skilled welders.

What You Gain With Robotic MIG

- Uniform, clean welds that rival TIG aesthetics

- Faster cycle times to keep up with demand

- Simple to run — no coding, no robotics expertise

- Free up your best welders for high-value projects

- Lower costs with quicker setup and fewer consumables

Beacon makes precision welding repeatable and scalable, so you can meet production goals without sacrificing craft.

VS

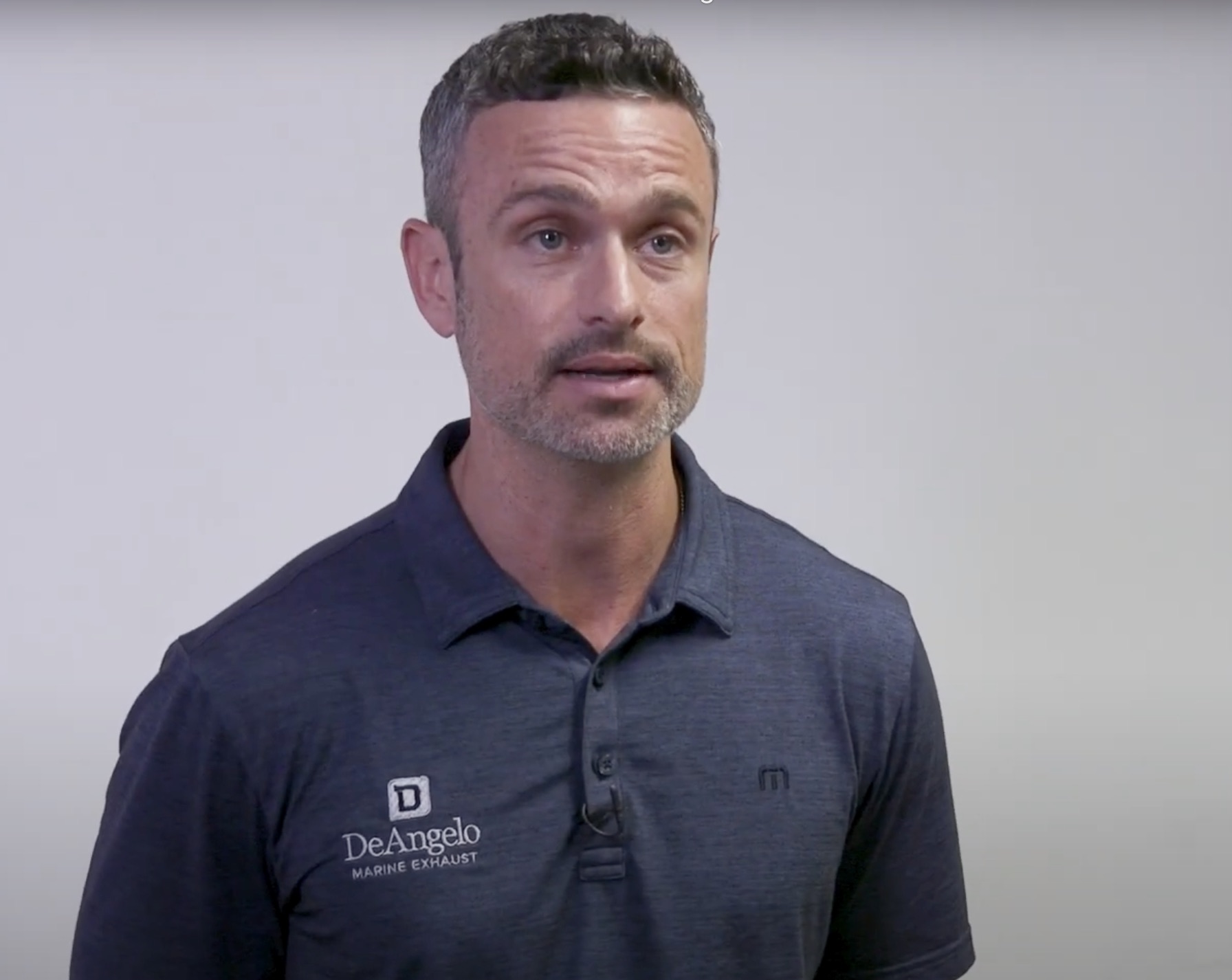

Customer Success Story

“We do everything by hand, TIG weld, that’s an art—2in to 5in a min if you’re good. We have the cobot, doing 20in a min. Thats how much capacity I’v gained.”

Justin Montes

CEO of DeAngelo Marine Exhaust