The Customer

How Tank Technology Cut Plasma Cycle Time by 94%, and Transformed Their Workflow with Hirebotics

From hand-cutting challenges to production breakthroughs – how a team of 50+ makers redefined precision and speed.

WATCH THE VIDEO

How Tank Production Shop Eliminated Rework With Cobot Plasma Cutter

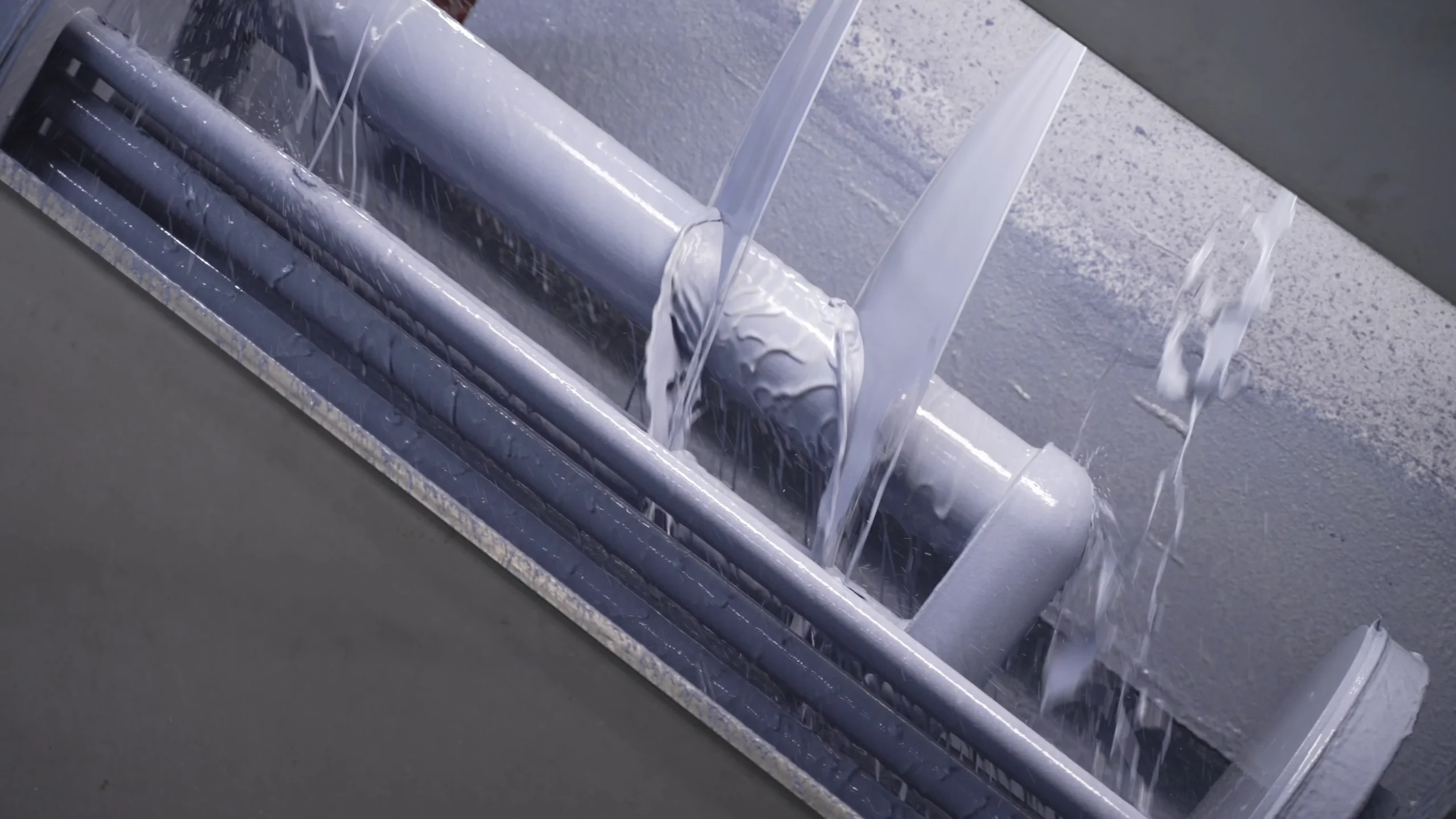

Tank Technology Inc., an employee-owned manufacturer of custom porcelain-lined water heaters, knew their cutting process was holding them back. A quarter of their product line was built-to-order, with custom diameters, shapes, and fittings. But their tools weren’t keeping up.

Manual cutting meant unpredictable results, constant rework, and cycle times that slowed everything down. Even with a skilled team, variability was baked into the process. And traditional CNC machines? They couldn’t handle the custom geometries that Tank Technology needed every day.

That’s when the team turned to Hirebotics.

The Challenge

Custom Parts, Complex Geometries, and Constant Rework

Manual cutting wasn’t just slow – it introduced variability at the exact point where precision mattered most. Complex tank designs, curved surfaces, and non-standard fittings pushed existing tools to their limits. Errors turned into rework. Rework turned into waste.

Tank Technology needed a cutting solution that could adapt to high-mix production without compromising speed or quality.

“25% of our products are customizable, so we were getting a lot of volatility and inconsistency when cutting our heads and bases by hand.”

Dan Church

Senior Manufacturing Engineer at TTI

The Solution

A Smarter Way to Cut with Beacon

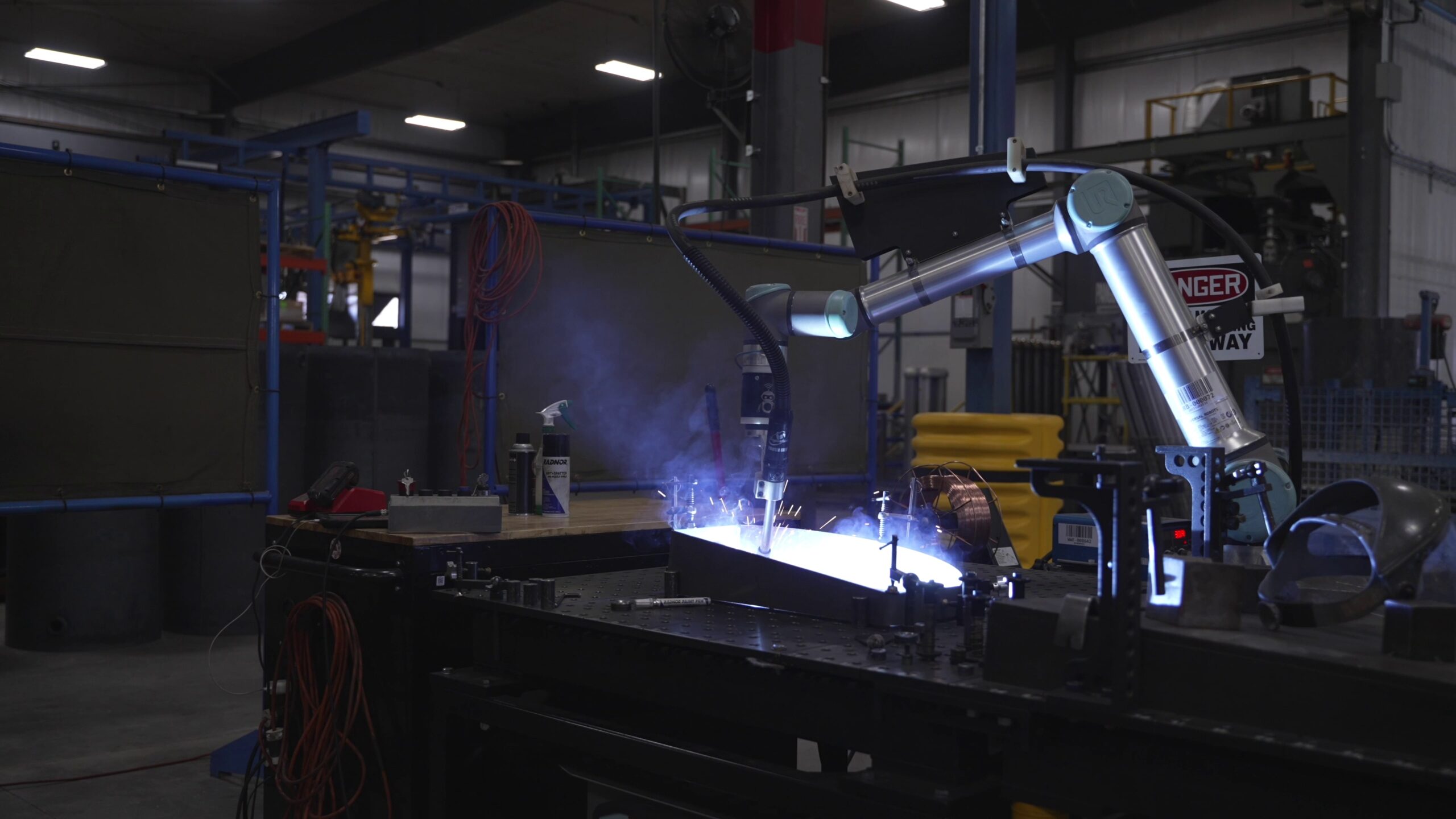

Tank Technology deployed the Beacon Cobot Cutter – an all-in-one plasma cutting solution designed for high flexibility and fast setup. With a compact footprint and multi-axis reach, it was tailor-made for the variable geometries their products demanded.

And setup? It was running in production within hours.

“The Cobot offered us all the axes we need to [accommodate] the geometry”

– Dan Church, Senior Manufacturing Engineer

Beacon’s app-based control system made the difference. Operators could get up and running fast, with no robotic experience required. Monitoring and control happened from a phone or tablet – no teach pendant, no complexity.

Training was straightforward, as staff members found the Beacon app interface intuitive.

“In the span of a week, [we] were programming and cutting [our] own parts.”

Eric Parmenter, ASME Production Lead.

The Results

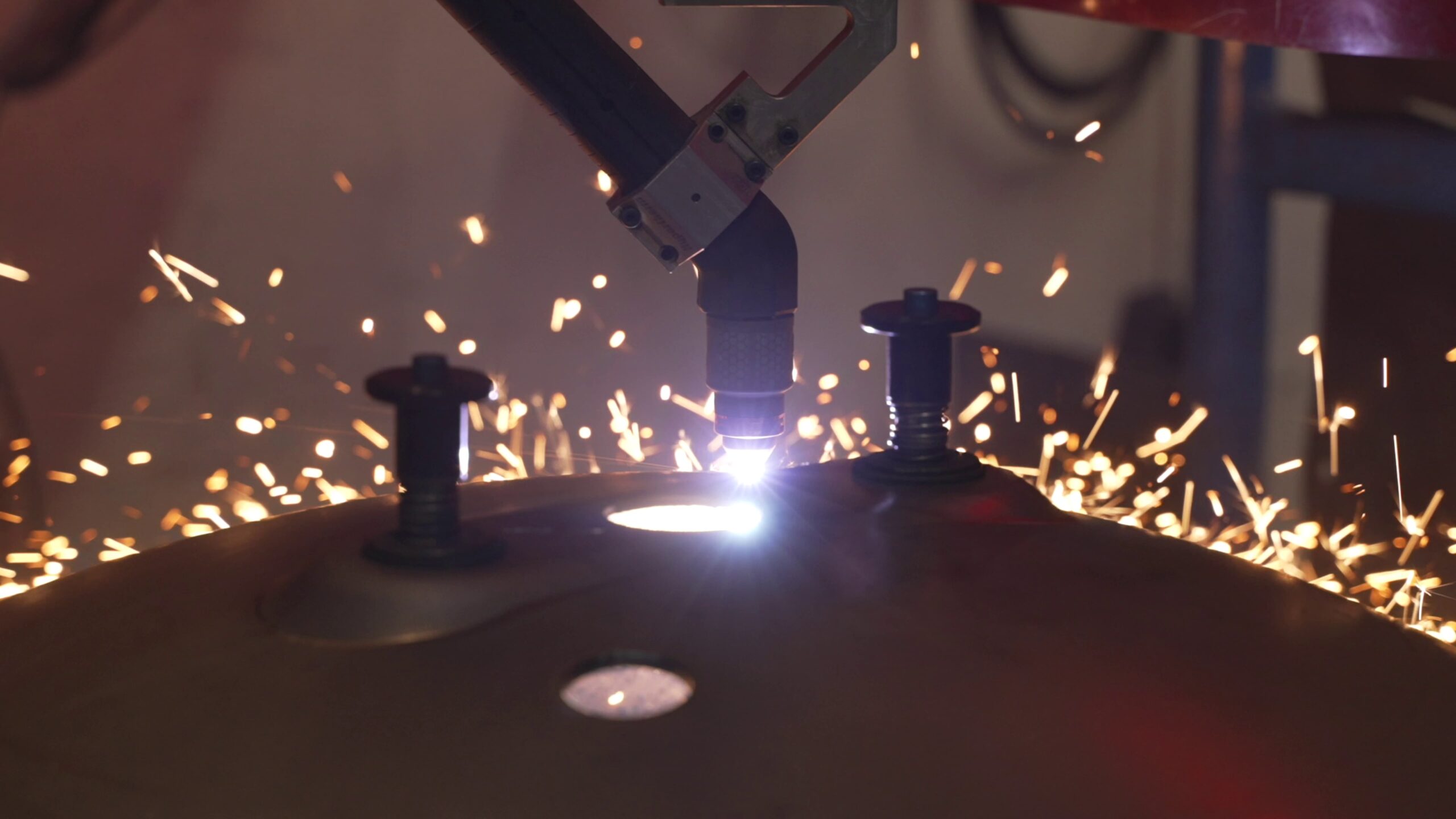

94% Faster Cuts, Zero Rework, and New Product Possibilities

The impact was immediate:

- New product capabilities unlocked

- Cycle time cut from 3 minutes to 11 seconds

- Rework dropped from 25% to nearly zero

“With the Beacon Cobot Cutter, we’re seeing perfectly sized holes in perfect locations – every time.”

– Eric Parmenter

Thanks to the precision and repeatability of Beacon’s system, Tank Technology began automating additional steps upstream. They even started plasma-cutting parts they previously thought were impossible – like beveled heads and bases with compound curves.

“We were able to add products to plasma cutting we didn’t even think we could add before.”

– Eric Parmenter

A Better Experience for Operators, Too

Beyond output and accuracy, Beacon transformed the day-to-day experience on the floor. Manual plasma cutting was physically demanding and mentally draining. Now, with automation, workers can focus on quality, oversight, and programming – without the strain.

The shift didn’t replace jobs. It made them better.

Tank Technology now sees Beacon-powered automation as a key part of their future: scaling efficiently, improving safety, and attracting skilled workers who want to work with modern, intuitive tools.

“If I knew about this product sooner, we would have moved forward a lot sooner.”

Dan Church

Before

After

See What’s Possible with Hirebotics

When flexibility, speed, and precision matter – Hirebotics helps fabrication teams take control of their production. The team at Tank Technology didn’t just automate a task – they unlocked a smarter, more scalable way to build.

Ready to do the same?