Iron Supports Boosts Productivity, Reduces Scrap, and Adds Capacity – All Without Hiring a Programmer

What began in a garage – with a welder, a farming work ethic, and a passion for building custom brackets – has grown into Iron Supports, a fast-moving fabrication business with a reputation for precision and speed.

But as orders surged and labor shortages tightened, Iron Supports hit a wall.

“We were turning down work. Not because we didn’t want it – but because we couldn’t keep up.”

Ryan Hansen

President of Iron Supports

The Challenge

Growing Demand, Limited Resources

Iron Supports faced two problems that many small shops will recognize: not enough welders, and not enough time to train or hire a dedicated robot programmer.

They explored traditional automation. But the systems they evaluated were either too complicated, too slow to deploy – or required months of implementation time they simply didn’t have.

What they needed was a system that was fast to install, easy to use, and flexible enough to adapt to their workflow.

“We weren’t looking for a six-month implementation. We needed a robot that could run next week.”

– Ryan Hansen

The Solution

Plug, Weld, Grow

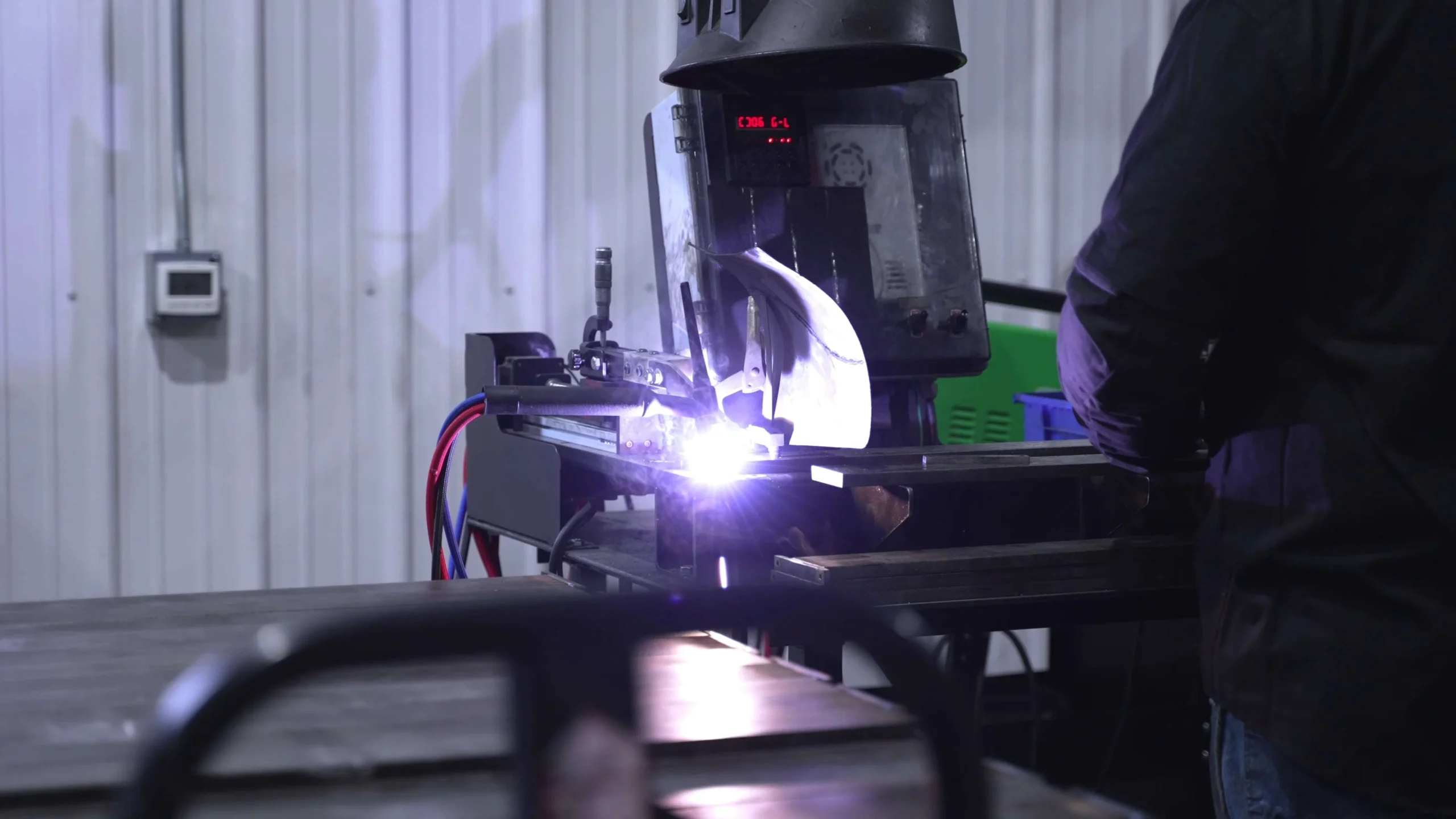

That’s when Iron Supports found the Cobot Welder from Beacon Robotics.

With its intuitive interface, no-code setup, and rapid deployment, the Cobot Welder delivered exactly what they needed: automation without the learning curve.

“We wired the money and had that thing up here in a week. And we were literally using it in production within two days of plugging it in.

– Ryan Hansen

“We got the cobot in the afternoon… and by four or five o’clock, it was running. I programmed a part at home that night. By morning, we were making welds.”

– Jeff, Shop Lead

The Results

More Output, Less Scrap, Zero Bottlenecks

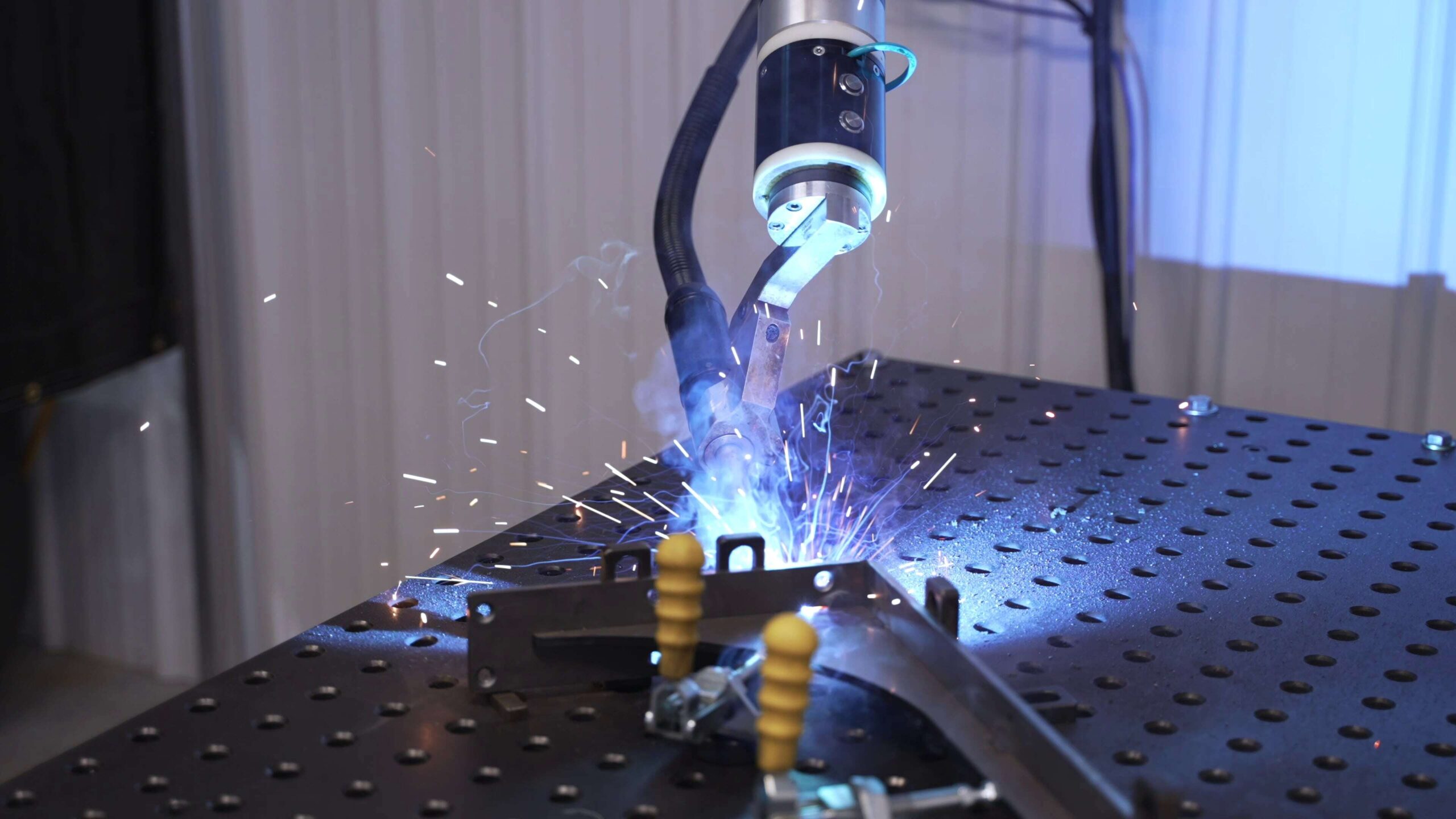

The Cobot Welder didn’t just help Iron Supports keep up – it pushed them ahead.

Cleared backlog

Within weeks, the team caught up on overdue orders and began working ahead.

Increased productivity

Welders could offload repetitive jobs to the cobot and focus on complex builds.

Reduced scrap

Weld quality became more consistent, thanks to reliable fixturing and repeatable results.

No programmer required

Any team member could program and run new jobs – without external support.

“The impact has been massive. We can test and tweak a new fixture, reprogram the cobot same day, and be in production hours later. Any one of the welders can do that.”

Ryan Hansen

President of Iron Supports

A Future Built on Flexibility

For Iron Supports, the Cobot Welder has become more than a tool. It’s a productivity engine – one that’s unlocked new capacity, improved quality, and put them back in control of their production schedule.

“Quality-wise, it’s night and day. There’s just no way to hand-weld the same part hundreds of times and expect perfection. With the cobot, we’ve drastically reduced rework.”

– Ryan Hansen

Beacon Robotics helps businesses like Iron Supports automate smarter – no programming, no delays, no compromises.

If you’re ready to take on more work, without adding headcount or complexity, the Cobot Welder is ready to go.

Plug in. Power up. Start building.