The Customer

DeAngelo Marine Cuts Welding Time by 90% with the Cobot Welder

DeAngelo Marine Exhaust builds high-performance exhaust systems for some of the most elite vessels on the water – from custom yachts to U.S. Navy fleets. With decades of experience behind them, their team is known for precision craftsmanship, quality, and reliability.

But when their order volume surged, their manual TIG welding process couldn’t keep up.

“I’m not about to promise a hundred ship sets to a customer, then miss the deadline by two weeks. That’s how you lose the account – and never get it back.”

Justin Montes

CEO, DeAngelo Marine Exhaust

The Challenge

A Skilled Labor Bottleneck

DeAngelo’s skilled welders were stretched thin. Jobs were piling up. The backlog was growing. And new orders from clients like the Coast Guard were landing faster than the team could build.

Speeding things up meant finding a better way to weld – but quality couldn’t slip, and TIG welding custom marine components isn’t something most machines handle well.

Justin explored automation. He sent parts to seven different welding companies. None came back meeting DeAngelo’s standards.

The Solution

A Better Way to Weld

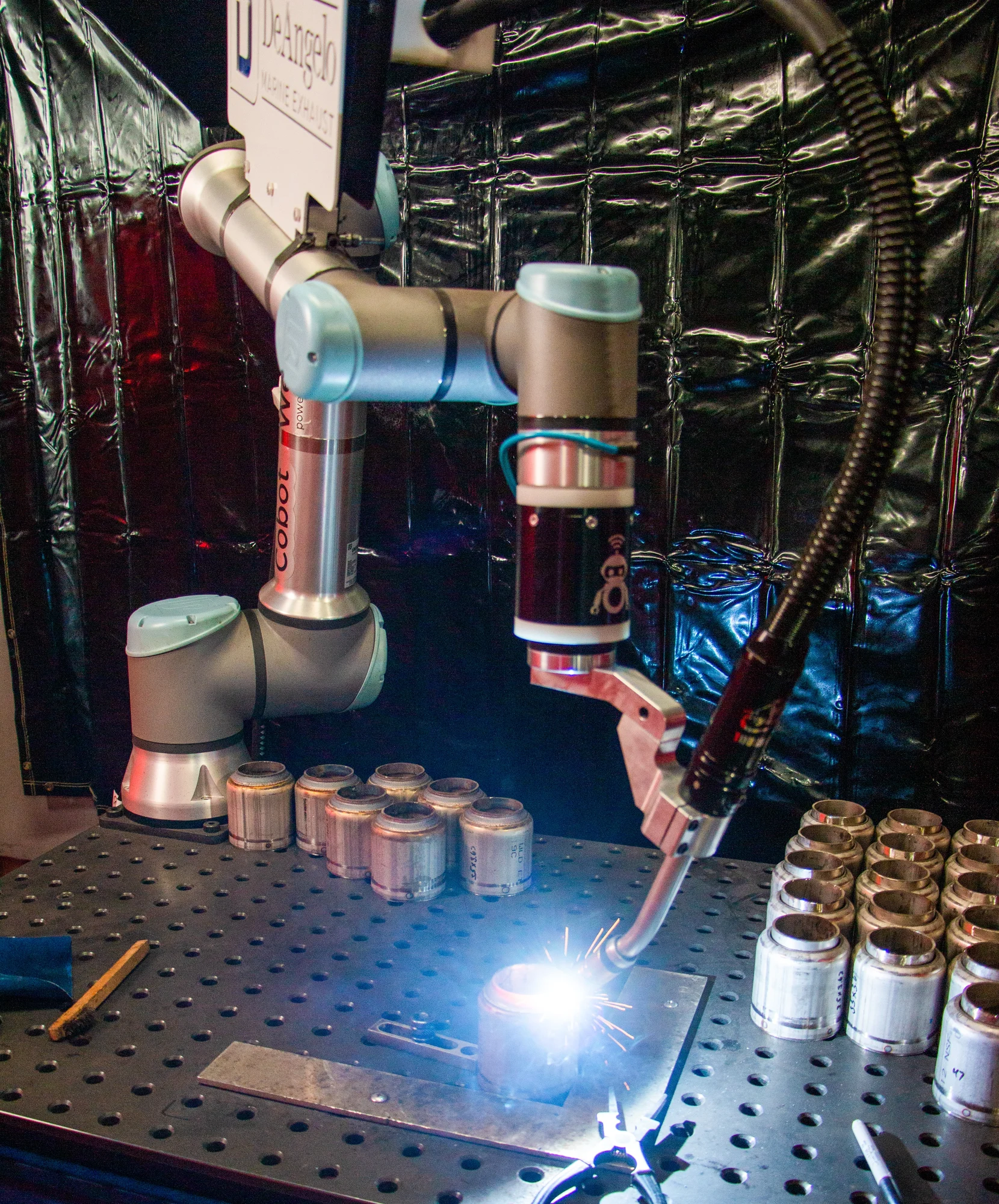

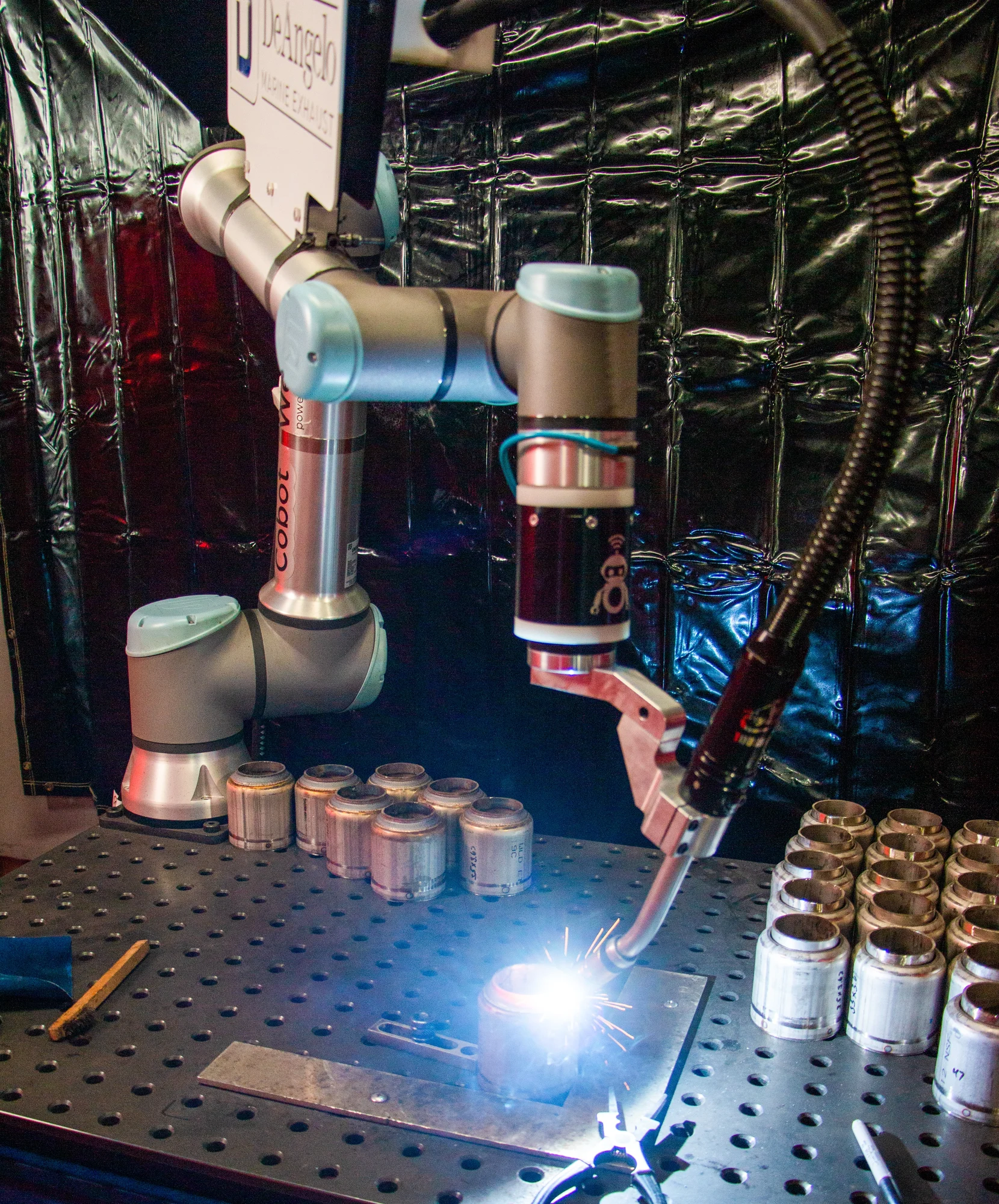

Then Beacon Robotics delivered a demo weld that matched the high standards DeAngelo is known for. But the real surprise came during implementation.

“Twenty minutes after setup, I was welding like I’d been running robots my whole life.”

– Justin Montes

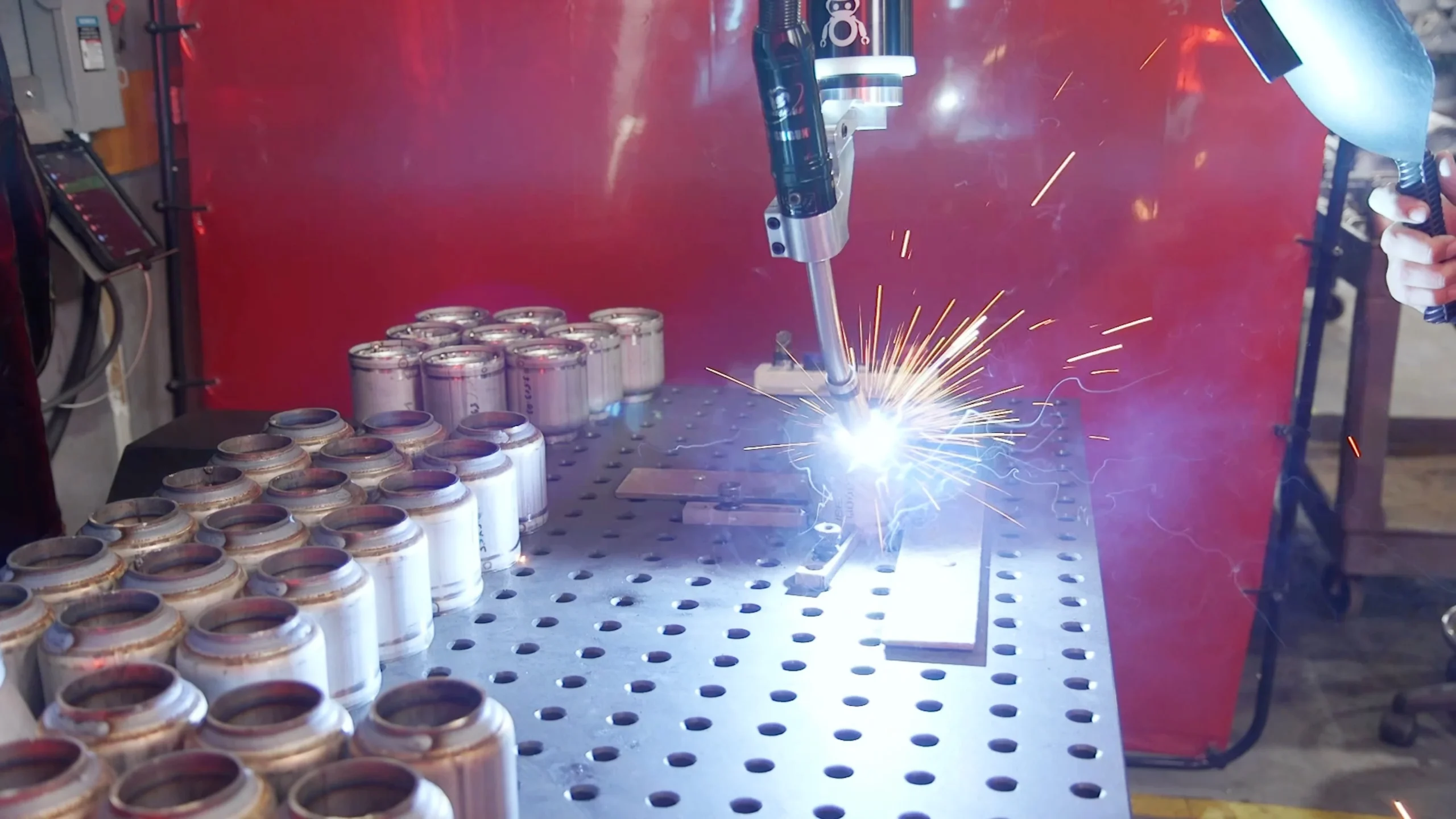

The Cobot Welder, powered by Beacon software, delivered both speed and simplicity – without the learning curve. No complex programming. No headaches. Just intuitive control, precision performance, and fast results.

WATCH THE VIDEO

The Results

Speed, Scale, and ROI. Impact was immediate.

Weld speed increased 10X

From 2 inches per minute with TIG…to 20 inches per minute with the Cobot Welder.

Backlog cleared in weeks

With production bottlenecks gone, the team caught up – and stayed ahead.

One job paid for the cobot

A Coast Guard order required 200 inches of weld per unit. Manually, it would take 100 minutes per piece. With the Cobot Welder? 10 minutes. That single project covered the full cost of the system.

The Future

Scaling Success

DeAngelo is now planning to scale the solution across the shop floor – envisioning a cobot at every lead fabricator’s table.

“Our long-term plan? Seven cobots. Seven arms. All running parts every day.”

– Justin Montes

What Other Shops Can Learn

DeAngelo’s story is a clear blueprint for any manufacturer facing skilled labor shortages, rising demand, or process bottlenecks:

- Automation doesn’t mean compromise. The Cobot Welder delivered production-grade quality – even on complex parts.

- Implementation is faster than you think. Setup took minutes. No robotics background required.

- ROI can come fast. One job paid for the system.

- You don’t need to wait to scale. Once you see results, it’s easy to replicate across your operation.

Beacon Robotics empowers fabricators to do more with the team they already have. If you’re ready to speed up production without sacrificing quality, the Cobot Welder is built for you.