Advanta Southeast faced numerous challenges with its welding operations. Due to the global pandemic exacerbating an already tight labor market and an increase in competition for welders in the region, the company was looking for a technological solution that could:

The Advanta Southeast team was hesitant about implementing traditional welding robots due to the long lead times to receive the equipment, training welders to use it, and above all, the complexities of programming the machines.

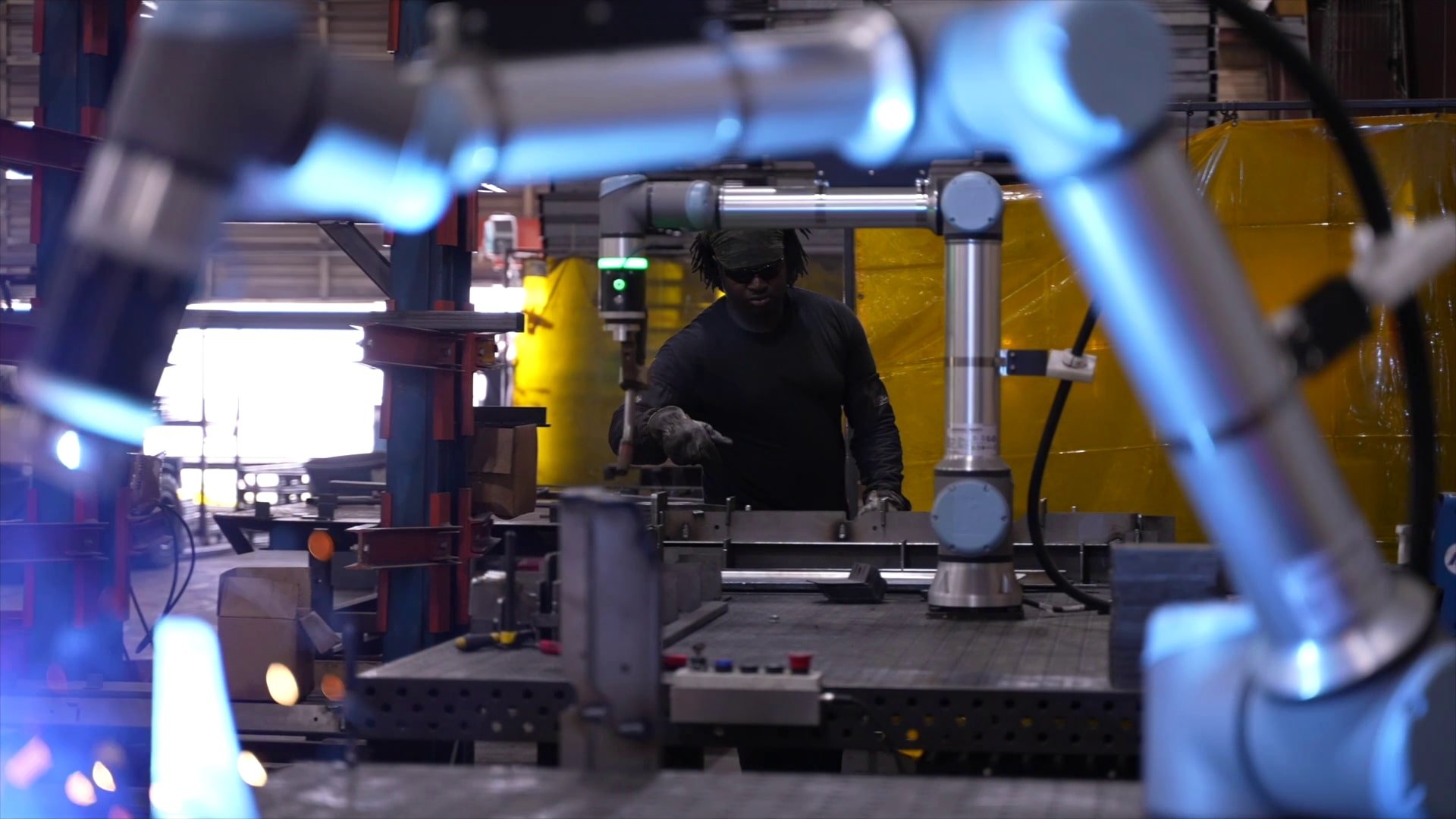

Advanta Southeast decided to acquire a Cobot Welder unit from Hirebotics to test it out. “When it comes to robotics, it was new for us. The last technology we learned was twenty-five years old. We didn’t have the experience or team to set up. That is why we chose Hirebotics,” Mark explained.

“We literally got our cobot from Hirebotics within two weeks. We were up and running on the day we received it,” he said. For the initial unit, Mark requested that a Hirebotics expert help him. However, once he saw how fast and easy it was to implement Cobot Welder, he knew he could do it himself.

“The setup was easy. From unboxing to getting it working, it’s a matter of a couple of hours—and you’re off to the races.” Mark indicated that it took less than a day of training for his welding team.

While there was initial pushback from the welding team, the welders soon realized just how easy Cobot Welder was to use and how it made their lives easier. “We ran the unit for about a month or so to get a feel for the usability and ease of access.”

The immediate impact of using Cobot Welder was welder efficiency. While the cobot carried out one job, the welders worked on other jobs manually. “We kind of get the best of both worlds,” Mark said. In addition, the welding team noticed more consistent and higher quality output.

“The main difference between Hirebotics’ Cobot Welder and traditional welding robots is that no programming is required. And the difference between Cobot Welder and manual welding is you can track everything from the app,” Mark added.

Apart from monitoring welding consistency, Advanta Southeast can now track in real-time different metrics, including the number of parts produced within a given period, gas and wire consumption, welder overtime, etc. Access to this data helps the companies make better and more accurate operational decisions.

Mark and the team found the app and Cobot Welder very easy to use. If any issues did arise, they would use the in-app chat function and get support within 5 to 10 minutes. “We have only to request support twice in seven to eight months. And usually, with that, we were back and running within 30 minutes.”

With the results of the first Cobot Welder unit, Advanta Southeast decided to acquire three more for the South Carolina plant and two for Advanta Industries in Michigan. Plans are underway to acquire more Cobot Welders in the not-so-distant future.

“We went from 25 parts to 100 parts a day within a matter of just a few hours after we set up the first unit. So, it increased our output to 400% compared with manual welding.”

“One of the biggest benefits that we've seen from buying Cobot Welder is our ability to go after contracts that we weren't able to get before. Now, we're doing a lot more tower projects. Actually, we’ve just been awarded a big project to build towers for an electric vehicle manufacturer.”

When asked whether he would recommend Cobot Welder to his peers, Mark answered: “I would tell anybody if they're on the fence or questioning it, go for it. They won't regret it.”

2025 Copyright. All rights reserved. Privacy Policy | Sitemap | Blog Sitemap